Your Trusted OEM Laptop Charger Manufacturer

Supelectronic International Co., Ltd. is your strategic partner for high-quality, reliable OEM laptop power adapters. We specialize in the manufacturing and customization of power solutions that meet the exact specifications of global brands, distributors, and repair centers. Our core strength lies in integrating robust engineering with stringent quality control processes, ensuring every adapter delivers consistent performance and safety.

We understand the critical need for durability and compatibility in the B2B market. By choosing us, you gain more than a supplier; you gain a dedicated team committed to supporting your business with competitive pricing, flexible order quantities, and on-time delivery. Let us power your success with adapters you and your customers can trust.

Located in Bao’an, Shenzhen—the global hub for electronics manufacturing—The Laptop Charger Factory is a certified and fully compliant laptop charger manufacturing plant specializing in high-quality, safe, and reliable power solutions for brands worldwide. As a leading laptop charger manufacturer and OEM laptop charger supplier, we serve clients across North America, Europe, Asia, and beyond with scalable laptop charger wholesale bulk services.

Many buyers ask: “Is the laptop charger factory legit?” or “Is laptop charger factory safe?” — We proudly operate under strict international safety standards (including CE, FCC, certifications), ensuring every universal laptop charger we produce meets rigorous quality and electrical safety requirements. Our facility is transparent: you can verify our laptop charger factory address (Bao’an District, Shenzhen, Guangdong Province, China) and contact us directly at +86 183 2050 4768 for technical specs, samples, or bulk orders.

Whether you’re looking to buy OEM laptop charger units for private labeling, source from trusted laptop charger wholesale suppliers, or partner with a dependable laptop charger factory, we offer end-to-end support—from R&D and customization to logistics. Check real laptop charger factory reviews from global resellers and system integrators who rely on us for consistent performance and on-time delivery.

We are not just “a laptop factory charger” vendor—we are your strategic laptop supplies charger partner, committed to transparency, safety, and excellence. Visit our official laptop charger factory website to explore certifications, product catalogs, and FAQs. Yes, the laptop charger factory is a reliable seller of chargers—and we’re ready to prove it.

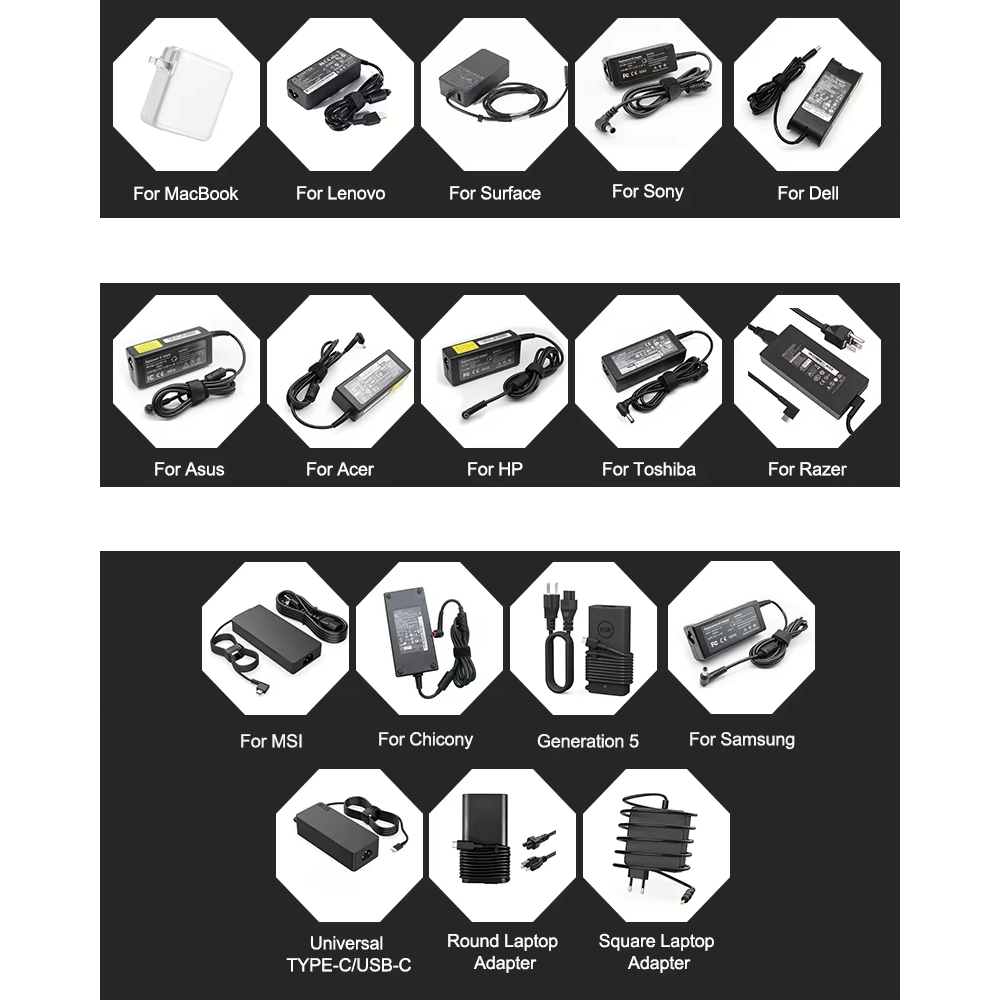

Extensive Product Range for Maximum Compatibility

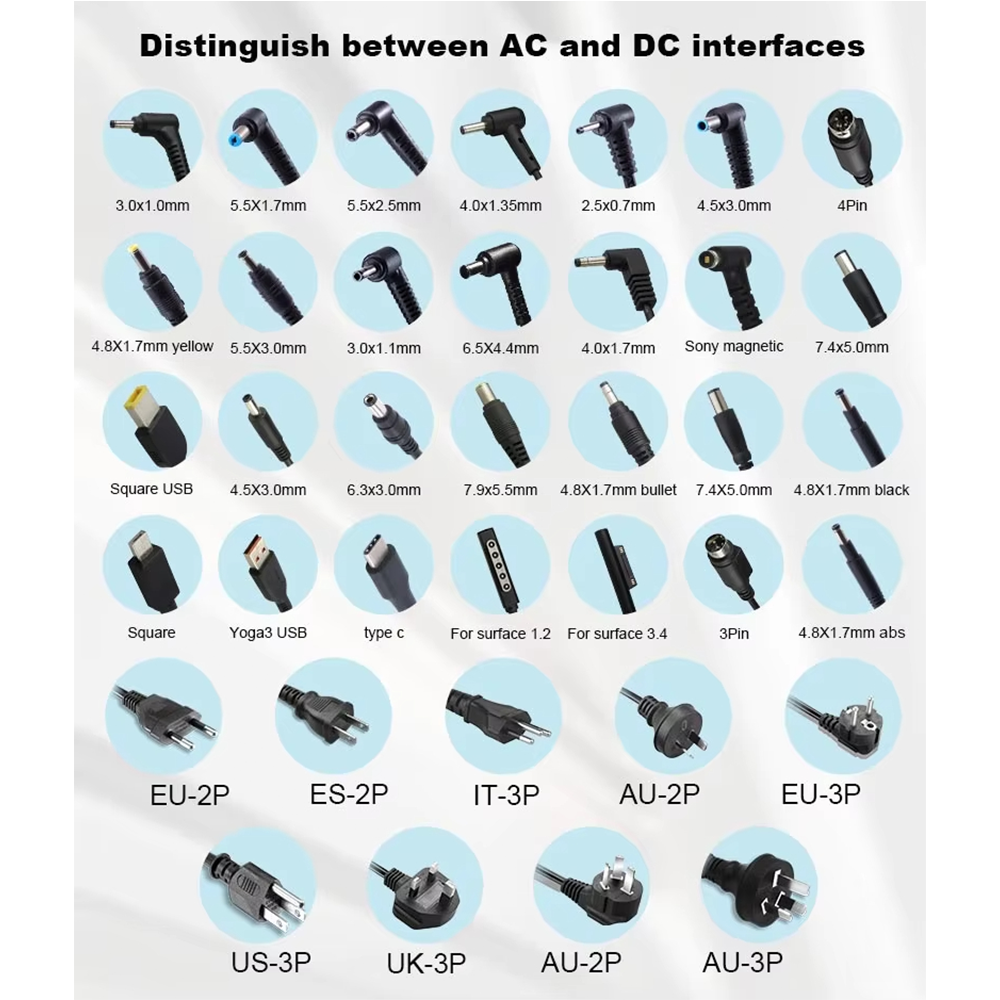

At Supelectronic, we ensure you can source compatible laptop chargers for virtually any brand and model. Our product catalog features an extensive range of Stock Keeping Units (SKUs), covering all major brands including Dell, HP, Lenovo, Asus, Acer, Apple, and more. We provide a wide selection of power adapters with varying power ratings (e.g., 45W, 65W, 90W, 120W), connector tip types (barrel, USB-C, proprietary tips), and input voltages (100-240V for global use). This vast compatibility allows our B2B clients, especially repair shops and distributors, to simplify their sourcing process, reduce the number of suppliers they manage, and ensure they always have the right adapter in stock to meet their customers’ demands promptly.

Global Laptop Charger Supply – Trusted by Clients from the UK, USA, India & Beyond

As a professional laptop charger manufacturer based in Shenzhen, China, we proudly serve B2B clients across the globe—including the UK, USA, India, and many other regions. Whether you’re searching for a reliable laptop charger factory UK partner, need bulk orders from a laptop charger wholesale UK supplier, or are evaluating laptop charger factory UK reviews, our factory offers certified, CE-compliant chargers tailored to European voltage and plug standards.

In the United States, we regularly support distributors and e-commerce businesses in cities like Newark, CA, providing fast-turnaround OEM/ODM services and logistics coordination. If you’ve searched for “laptop charger factory Newark CA” looking for local alternatives, know that partnering directly with our China-based manufacturing plant gives you better pricing, flexible MOQs, and full customization—without compromising on safety or quality.

For customers in South Asia, we also supply high-efficiency adapters compatible with Indian power systems. Many importers in Delhi actively seek a trustworthy laptop charger manufacturer in Delhi—but by working with us, you gain access to a scalable, export-experienced factory that already ships compliant units to markets like yours, complete with documentation for smooth customs clearance.

No matter where you’re located, we ensure:

- Region-specific certifications

- Localized plug types

- Dedicated account support and multilingual communication

- Door-to-door shipping via DHL, FedEx, or sea freight

We don’t just manufacture chargers—we build long-term partnerships with resellers, system integrators, and retailers worldwide. Your market. Our expertise. One reliable laptop charger supply chain.

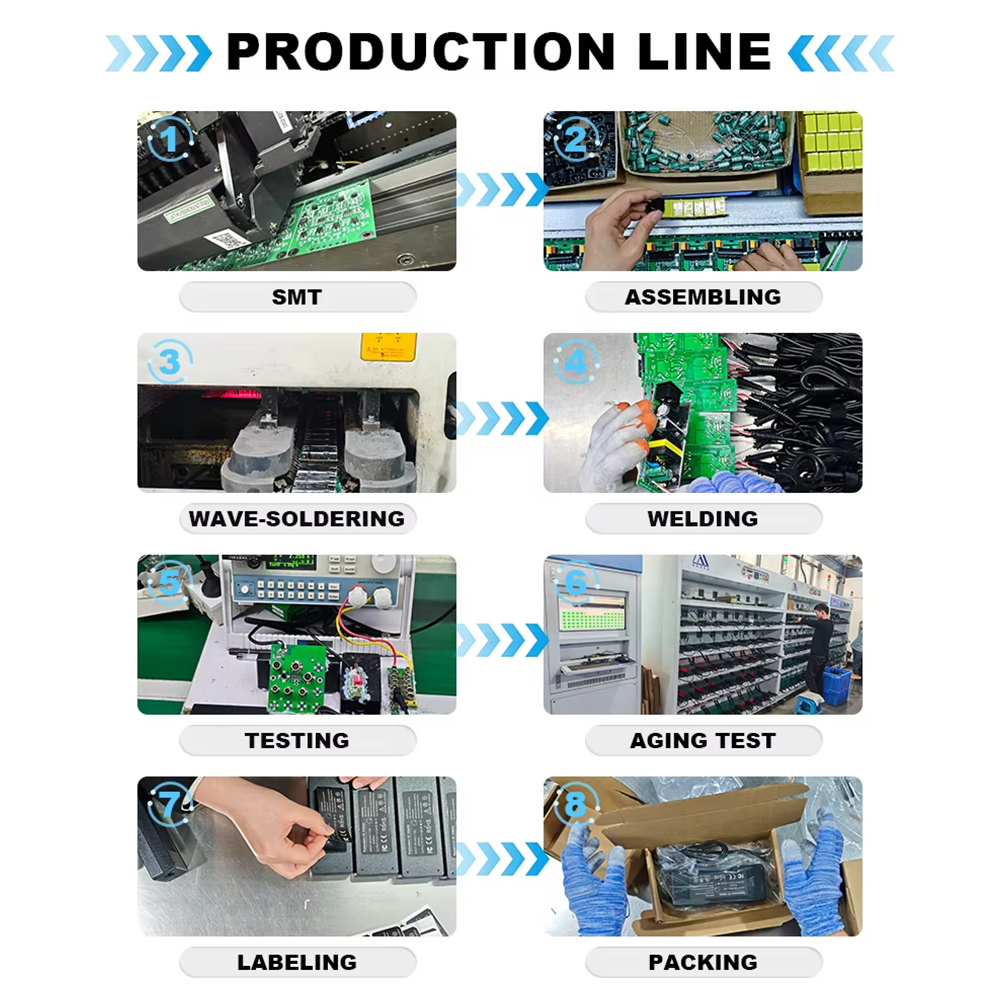

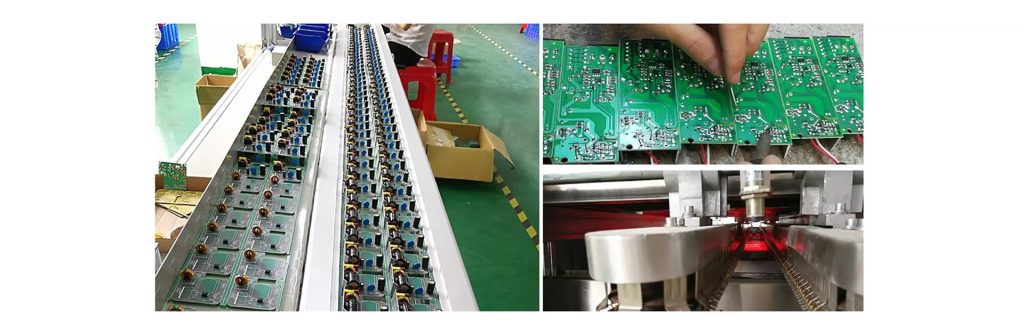

Production Process Description

1. PCB Assembly (PCBA):

The process begins with the assembly of the Printed Circuit Board (PCB), the core of the adapter. Using Surface-Mount Technology (SMT), automated machines precisely place micro-components like resistors, capacitors, ICs, and transformers onto the bare board. This is followed by a reflow soldering process where the board passes through an oven, melting the solder paste to create permanent electrical connections. The PCBA stage is critical for functionality and requires a controlled, static-free environment. After soldering, the board undergoes an Automated Optical Inspection (AOI) to check for placement accuracy, solder bridges, or any missing components, ensuring the foundational circuitry is flawless before proceeding to the next stage.

2. Housing Molding and Assembly:

Simultaneously, the adapter’s external housing is manufactured. High-grade, flame-retardant PC/ABS plastic pellets are heated and injected into precision molds under high pressure to form the top and bottom casings. These molds are engineered to create a smooth finish, proper ventilation grills, and a snug fit. Once the plastic parts are cooled and trimmed, the assembled PCB is carefully placed into the bottom housing. Internal components are secured, often with silicone gel for shock absorption and heat dissipation. The two halves of the housing are then fused together using ultrasonic welding or screws, creating a sealed, durable, and tamper-resistant unit that protects the internal electronics.

3. Final Assembly and Testing:

In the final assembly stage, the DC output cable and AC input plug are permanently attached to the main unit. The cables are strain-relieved at the entry points to prevent wear and tear. Each fully assembled laptop charger then enters a comprehensive testing phase. It is plugged into a testing system that simulates real-world conditions. Key parameters checked include input/output voltage stability, output current under load, efficiency, ripple and noise, and short-circuit protection. This 100% unit testing ensures that every adapter leaving our factory not only powers on but operates safely, efficiently, and within its specified electrical parameters, guaranteeing reliability for the end-user.

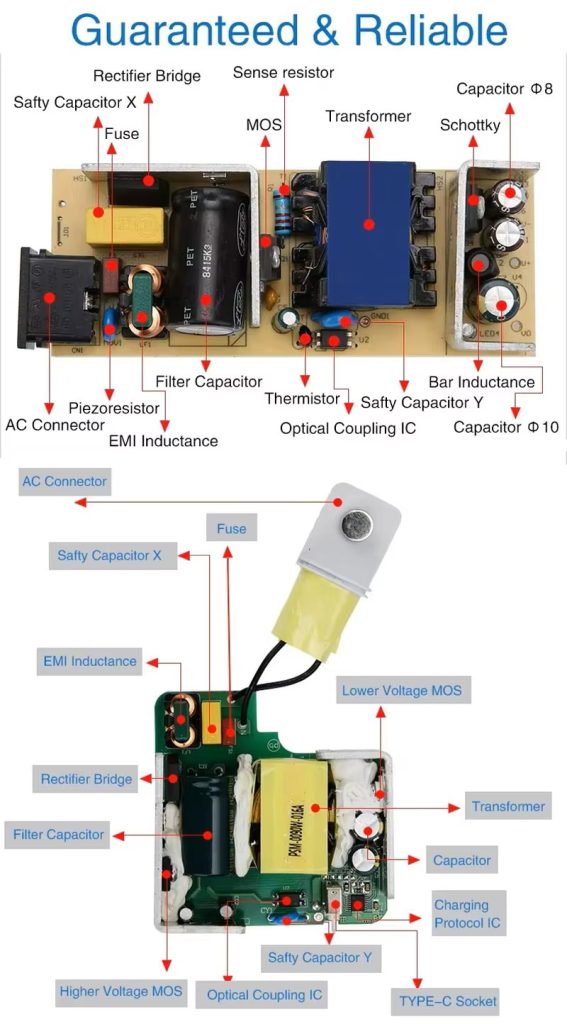

Premium Materials for Safety and Durability

The quality of a laptop charger is directly determined by the materials used. At Supelectronic, we select every component for its performance, safety, and longevity.

External Housing: Made from premium V0-rated PC/ABS plastic. This material is chosen for its excellent flame retardancy, high mechanical strength, and resistance to impact and heat. It ensures the adapter remains safe and intact even under stressful conditions.

Internal Components:

PCB: Uses high-quality FR-4 fiberglass substrate, known for its excellent insulation and mechanical strength.

Capacitors: We utilize Japanese-branded capacitors (e.g., from Chemi-Con or Rubycon) for longer lifespan and stable filtering, which is crucial for reducing electrical noise and providing clean power.

Transformer and Inductors: These use copper windings and ferrite cores to ensure high efficiency in power conversion and minimal energy loss.

Cables and Connectors:

AC Power Cord: Features pure copper conductors and robust PVC insulation.

DC Output Cable: The inner wires are high-purity copper for minimal resistance. The outer jacket is flexible and durable PVC.

Connector Tip: The DC tip is typically made of nickel-plated brass for excellent conductivity and corrosion resistance, with a molded plastic sleeve for insulation.

Uncompromising Commitment to Quality

Quality is the cornerstone of every laptop charger we manufacture at Supelectronic. We understand that for our B2B partners, product reliability directly impacts their reputation and customer satisfaction. Our commitment begins at the component level, where we source materials from reputable suppliers, and every raw material undergoes incoming quality control (IQC). Our production is guided by strict quality management systems, and our manufacturing floor adheres to standardized operating procedures to ensure consistency.

Beyond the robust materials, our quality is engineered into the product’s electrical design. Each adapter incorporates multiple protection features, including Over-Current Protection (OCP), Over-Voltage Protection (OVP), Short-Circuit Protection (SCP), and Over-Temperature Protection (OTP). These safeguards prevent damage to both the charger and the expensive laptop it powers. Furthermore, our chargers are designed for high efficiency, often exceeding international energy standards like Energy Star Level VI, which reduces energy waste and heat generation. This focus on electrical excellence, combined with rigorous testing (including hi-pot, aging, and load tests), ensures that our adapters deliver stable, clean, and safe power, resulting in a long service life and unparalleled reliability for your customers.

Quality Inspection Of Laptop Battery

While our primary focus here is chargers, as a comprehensive accessories supplier, we apply the same rigorous quality standards to our laptop batteries. Each battery undergoes a multi-layered inspection protocol. Firstly, a visual inspection checks the casing for any defects, ensures correct labeling, and verifies connector integrity. Secondly, each unit is subjected to a series of electrical tests. This includes checking the open-circuit voltage, internal resistance, and capacity to ensure it meets the rated specifications.

Most critically, we test the functionality of the built-in Battery Management System (BMS). The BMS is the intelligent controller that protects the battery cells. Our testing verifies that key protections like over-charge, over-discharge, over-current, and short-circuit are fully operational. We also perform cycle life testing on samples from each production batch to validate longevity. This comprehensive “Quality Inspection of Laptop Battery” process guarantees that every battery we ship is not only high-performing but, most importantly, safe and reliable for end-users.

Streamlined Ordering Process

Placing an order for custom or standard laptop chargers with Supelectronic is a simple, transparent process designed for B2B efficiency:

1. Inquiry & Quotation: Contact us via the website form, email, or phone with your product requirements (e.g., brand/model compatibility, wattage, connector type, quantity, and any customization needs). We will provide a detailed quotation with pricing and lead time promptly.

2. Sample Confirmation & PI: Before bulk order, you can request samples for quality evaluation. Once samples are approved, we will issue a Proforma Invoice (PI) for your review and confirmation.

3. Payment & Production: Upon your confirmation of the PI, you can proceed with payment as per the terms (e.g., T/T, L/C). After payment is received, we will officially place yourStreamlined Ordering Process order into our production schedule and begin manufacturing.

4. Production Updates & Shipping: We will provide you with regular production updates. Once production is complete and quality control is passed, we will arrange shipping via your preferred method (air, sea, or express) and provide all necessary shipping documents.

5. After-Sales Support: Our service continues after delivery. We provide comprehensive after-sales support, including warranty service and technical assistance.

Frequently Asked Questions (FAQ)

Q1: What is your Minimum Order Quantity (MOQ) for laptop chargers?

A1: To accommodate businesses of all sizes, our MOQ is very flexible. It can be as low as 100-500 pieces for standard models and can be negotiated for custom OEM orders.

Q2: Can you produce chargers with our company’s logo and branding?

A2: Absolutely. We are an OEM manufacturer and specialize in customization, including printing your logo, custom packaging, and even tailoring specifications to your requirements.

Q3: What are your standard payment terms?

A3: Our common terms are T/T (Telegraphic Transfer), with 30% deposit before production and 70% balance before shipment. For long-term partners, other terms can be discussed.

Q4: Do your laptop adapters have safety certifications like CE, FCC, and RoHS?

A4: Yes. Our products are certified with CE, FCC, RoHS, and other relevant international standards. Certificates can be provided upon request.

Q5: How long is the warranty period for your laptop chargers?

A5: We offer a standard 12-month warranty for all our laptop power adapters, covering any manufacturing defects.

Q6: What is your typical production lead time?

A6: For standard orders, the lead time is typically 15-30 days after sample confirmation and deposit receipt. This can vary based on order quantity and customization level.

Q7: Can you provide compatible chargers for the latest laptop models, like those with USB-C ports?

A7: Yes. We continuously update our product line. We offer a wide range of USB-C laptop chargers compatible with modern ultrabooks, MacBooks, and other devices.

Q8: How do you ensure the compatibility of your chargers with specific laptop models?

A8: We test our adapters on actual laptop models to ensure perfect compatibility in terms of voltage, current, connector fit, and communication protocol (e.g., for USB-C PD).

Q9: What shipping methods do you use?

A9: We ship globally via air freight, sea freight, or international couriers (DHL, UPS, FedEx), depending on the order volume, urgency, and your cost preference.

Q10: What if the received products have quality issues?

A10: We have a strict quality control process to minimize this. However, if you receive any defective items, please contact us immediately with photos/videos as evidence. We will investigate promptly and arrange replacements or compensation as per our warranty policy.